My Journey Started…

Laser cutting and engraving is a fascinating and rewarding hobby that can also turn into a profitable business. However, choosing the right laser machine for your needs can be a daunting task, especially if you are new to the field. There are many types of lasers, each with their own strengths and weaknesses, and each suited for different applications and materials. In this article, I will share with you some of the things that I considered when researching laser options, and how I found the best laser machine for my hobby.

What Are the Different Types of Lasers?

One of the first things that I learned is the difference between diode, CO2 and fiber lasers. These are the three main types of lasers that are used for cutting and engraving. Diode lasers are the cheapest and most compact ones, but they also have the lowest power and speed. They can cut and engrave on thin materials such as wood, paper, leather and acrylic. CO2 lasers are more expensive and bulky, but they also have higher power and speed. They can cut and engrave on thicker materials such as wood, acrylic, glass, metal and stone. Fiber lasers are the most advanced and costly ones, but they also have the highest power and speed. They can cut and engrave on almost any material, including metal, ceramic, plastic and rubber.

What Kind of Materials Do I Want to Work With?

Another thing that I considered is what kind of materials I want to work with. Different materials have different properties and require different settings and techniques. For example, wood is a natural material that can vary in density, grain and moisture content. It can be easily burned or charred by the laser beam if not handled properly. Acrylic is a synthetic material that can melt or crack under high temperatures. It can also produce toxic fumes when cut or engraved by the laser. Metal is a hard material that can reflect or absorb the laser beam depending on its type and thickness. It can also generate sparks or flames when cut or engraved by the laser.

The type and thickness of the material also determined the power source of my laser machine. Most affordable laser machines use either diode, CO2 or fiber lasers as their power source. Diode lasers are the cheapest and most compact ones, but they also have the lowest power and speed. They can cut and engrave on thin materials such as wood, paper, leather and acrylic. CO2 lasers are more expensive and bulky, but they also have higher power and speed. They can cut and engrave on thicker materials such as wood, acrylic, glass, metal and stone. Fiber lasers are the most advanced and costly ones, but they also have the highest power and speed. They can cut and engrave on almost any material, including metal, ceramic, plastic and rubber.

Do I Want to Start With a Low-Cost Unit or Invest in a High-Quality One?

A third thing that I considered is whether I want to start with a low-cost unit and upgrade later, or invest in a high-quality one from the beginning. This depends on my budget, my goals and my expectations. A low-cost unit can be a good way to learn the basics of laser cutting and engraving without spending too much money. However, it might also have some limitations in terms of power, speed, accuracy and durability. A high-quality unit can be a better option if I want to achieve professional results and work on more complex projects. However, it might also require more maintenance, skills and safety precautions.

In my opinion, if you go for a low-cost unit, you shouldn’t expect to upgrade it later because going from a 2.5w or 5w to a 30w might require quite a few components such as power adapters, motherboard, laser, wires etc to be upgraded costing more than the new larger unit… My recommendation in this case is to just sell your old unit on Facebook marketplace, to a family member or on Craigslist or similar to recover some of your purchase.

What I’ve surmised thus far is most things can be done on the cheaper lasers as well as the stronger ones. For instance cutting through thicker things can be done in multiple passes on weaker machines but this is also much slower. Another thing to consider is build quality (picking a reputable brand) is my suggestion for longevity as well choosing a unit where you can clean and replace your lens.

What I chose for myself and my needs?

After doing my research, I decided to buy a diode laser from Sculpfun. They offered a 33w laser that could cut and engrave on a large area of over 900x900mm (almost 3ft x 3ft). I must say being able to cut and engrave at this size was the main reason I chose this unit (XTools was expandable to about half that size and it was MUCH more expensive as well they forced you to purchase both a 20w and 40w laser; which seemed ridiculous to me). I also bought their 800x800mm honeycomb bed, the rotary option and some other accessories. I’ll be posting photos, videos and my purchase options, decisions and issues I experience.

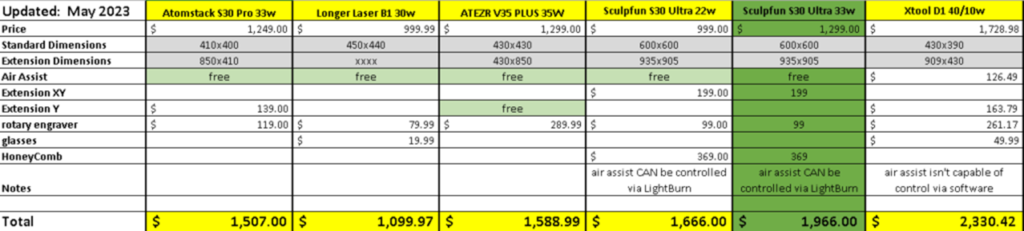

Below is a table I worked up to make my choices. I compared a few of the leaders in the diode laser realm who had >30w offerings. Then once I settled on Sculpfun I also added their 22w for comparison. Hope this helps someone out there trying to find their perfect option.

5 responses to “Purchasing a Laser Cutter Engraver – Decisions, Decisions”

Having read this I thought it was rather enlightening.

I appreciate you spending some time and energy to put this short

article together. I once again find myself personally spending a significant amount of time both reading

and leaving comments. But so what, it was still worth it!

Great post, you have pointed out some wonderful points, I besides conceive this is a very good website.

There’s definately a lot to know about this issue. I love all the points you’ve made.

Great article! I appreciate the clear and insightful perspective you’ve shared. It’s fascinating to see how this topic is developing. For those interested in diving deeper, I found an excellent resource that expands on these ideas: check it out here. Looking forward to hearing others’ thoughts and continuing the discussion!

Great read! I appreciate the thorough analysis presented. The examples really helped to clarify complex concepts. Does anyone else have additional insights or experiences to share on this topic?